What is Carbon Fiber?

What is Carbon Fiber Reinforced Plastic?

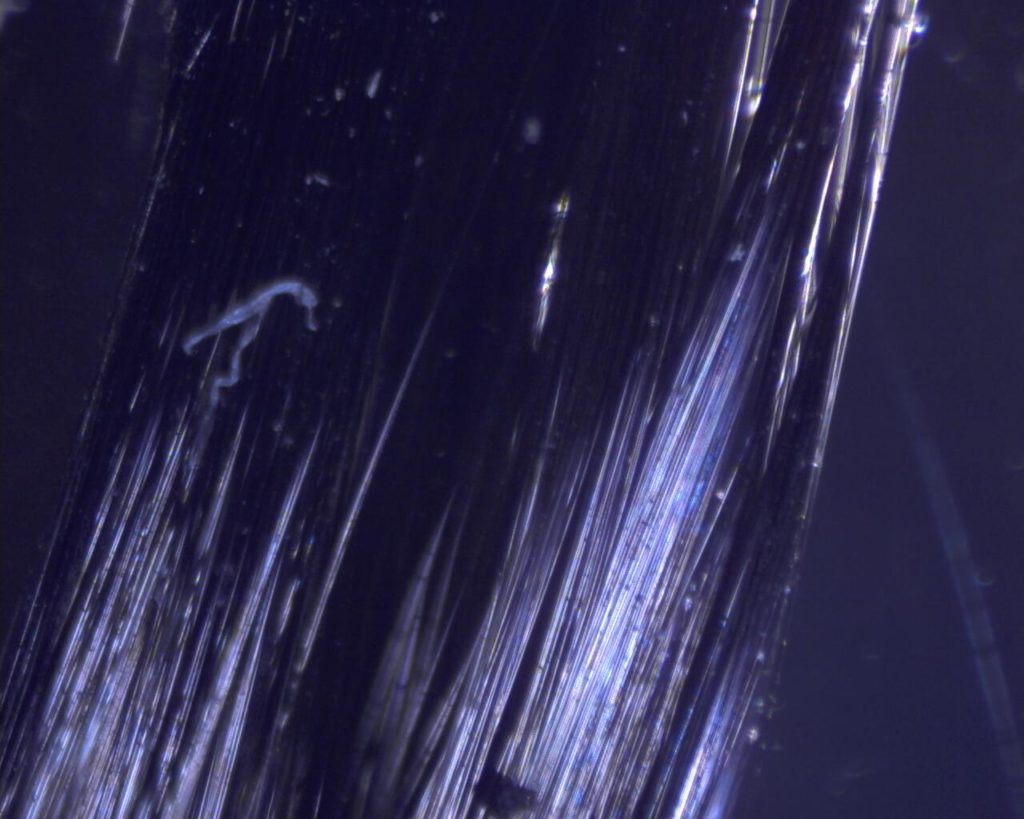

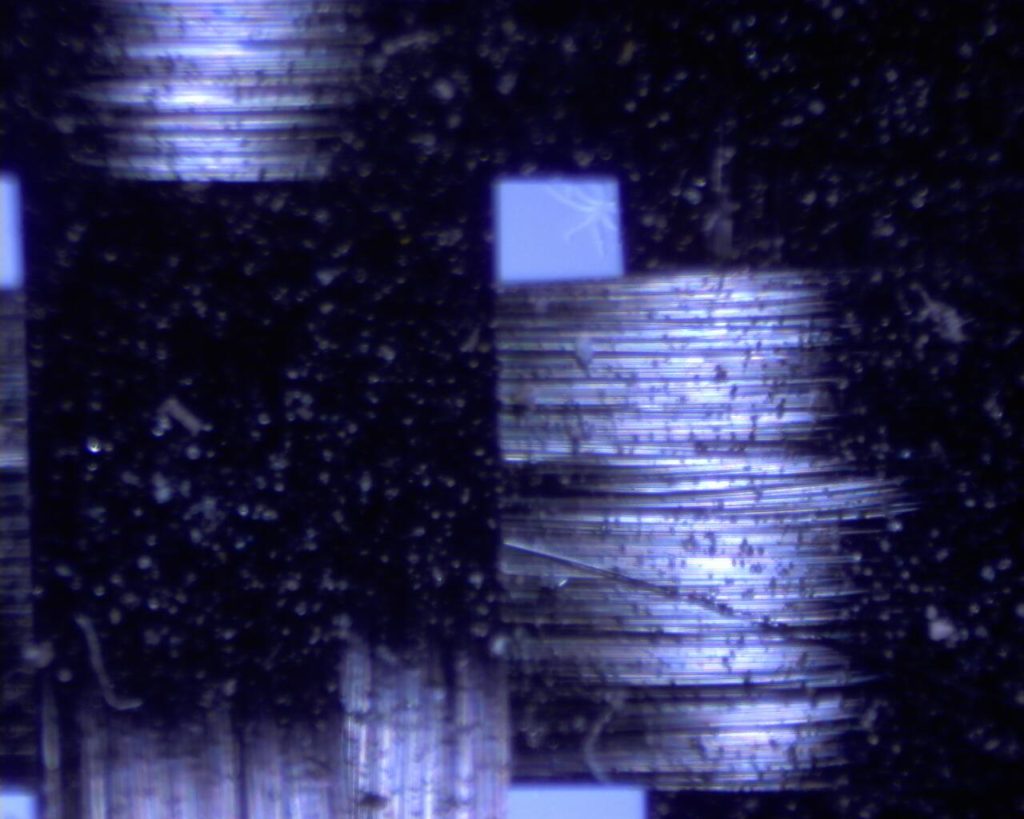

Carbon fiber reinforced plastic, or CFRP, comprises two components: high stiffness, high strength carbon fiber and a plastic matrix, typically a thermoset like epoxy. Individual carbon fibers are very thin, on the order of 5 to 10 microns wide, and are made in high intensity furnaces at over 2000 C. The structure of carbon fiber is such that each fiber has tremendous stiffness and strength along the axis of the fiber. This is one of the key principles of designing with carbon fiber (or any other fiber reinforced plastic, for example fiberglass, aramid, basalt, bamboo, etc) – that the stiffness and strength is in the direction of the fibers. For a given part, one can orient fibers in multiple directions, but if there are no fibers in a given direction, the mechanical properties (modulus, tensile strength, compressive strength, etc) will be greatly reduced compared with axes that have fibers oriented along them.

By utilizing different starting components, called precursors, different types of carbon fibers can be produced. The two primary versions in use are called Polyacrylonitrile (PAN) and Pitch carbon fibers. PAN carbon fiber is the common version most people are familiar with (about 90% of all carbon fiber produced are of the PAN variety). It comprises the standard and intermediate modulus fiber types with modulus of elasticity values typically ranging from about 30msi to 65msi. To achieve higher modulus values Pitch carbon fiber is used. Pitch carbon fibers can easily achieve 100msi or even higher modulus of elasticity values.

The question often arises, then, why not always use Pitch carbon fiber, since it is more rigid (i.e. high modulus). The answer is that, typically, stiffness and strength are inversely related for carbon fiber – as the modulus increases the strength decreases. For a given application, if higher strength is required, then the solution is almost always to use PAN carbon fibers. Pitch carbon fiber can be used to produce parts that are stiffer than steel, but strength will be sacrificed. The ideal applications for Pitch carbon fiber are usually those that will see low stresses, but require extremely small deflection. Robotic end-of-arm tooling is a common application that has these requirements. In addition, Pitch carbon fiber is usually more expensive than PAN options.

Carbon fibers alone are usually not very useful, since they cannot hold a compressive load on their own without another material holding them straight. This is the purpose of the matrix within the composite. The matrix stabilizes the carbon fibers so they can maintain their straightness while compressive loads are applied. It also transfers the internal stresses from fiber to fiber. One of the most common matrix materials is epoxy, which can be added to the carbon fibers by mixing two chemicals, a resin and hardener, and then applied with brushes, vacuum, presses, or any number of other methods. Some epoxy resin systems can be pre-added to the carbon fiber and only partially cured. This process usually requires the material to be kept below room temperature for storage and is called a prepreg carbon fiber material.

As an engineering material, carbon fiber reinforced plastics can be fabricated to have tailored mechanical properties along different axes by placing a greater percentage of the fibers in one direction, while sacrificing the percentage along an orthogonal axis.

To learn more about our carbon fiber composites products, click HERE. All manufacturing, including CNC machining, is performed in the United States by US citizens, so you will get quick turnaround, prompt service, and excellent quality.