Redesign of a Large Vertical Wind Tunnel Axial Fan

After a blade failure, Kumair engineers redesigned the aluminum blades on a large diameter fan used to power one of the largest outdoor vertical wind tunnels in the United States. Located at Appalachian Amusement Center in North Carolina, the company utilizes the large wind tunnel for sky diving training. The primary fan for the tunnel measures 14 feet in diameter and accelerates air to over 130 mph. At full power, the column of air can carry "fliers" up to 60 feet or more above the net.

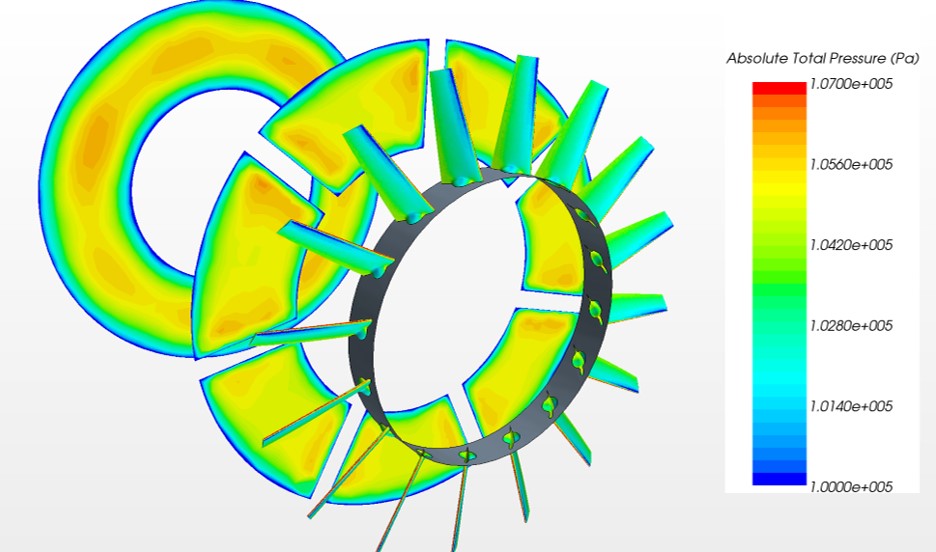

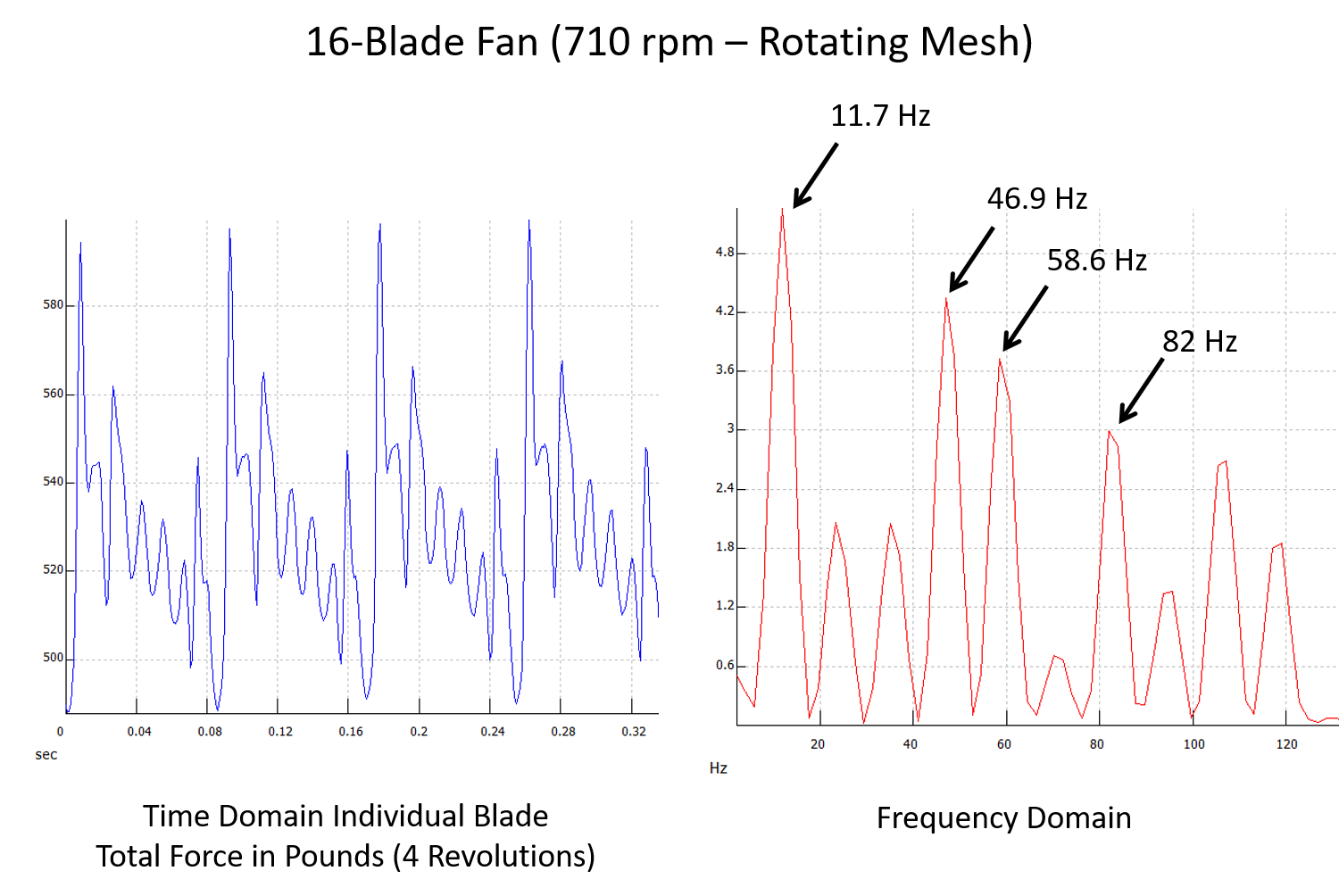

Blade interactions with support structure wakes caused excitation of the first bending mode, which in turn caused a fatigue failure. The re-engineering process first required careful CAD modeling of the system to accurately capture all of the important geometry. Next, FEA and CFD analyses were performed for the current blades and surrounding geometry, both upstream and downstream. Once the analysis was completed, the blades were redesigned to increase the natural frequency. One of the challenges, however, was that the hub could not be changed, so blade mass needed to remain close to the original to limit centrifugal force increases. CFD analysis of the full rotating 16-blade fan with support structure showed a number of potential excitation frequencies. The new blade design needed to avoid any bending or torsion mode interactions with these aerodynamic excitation forces.

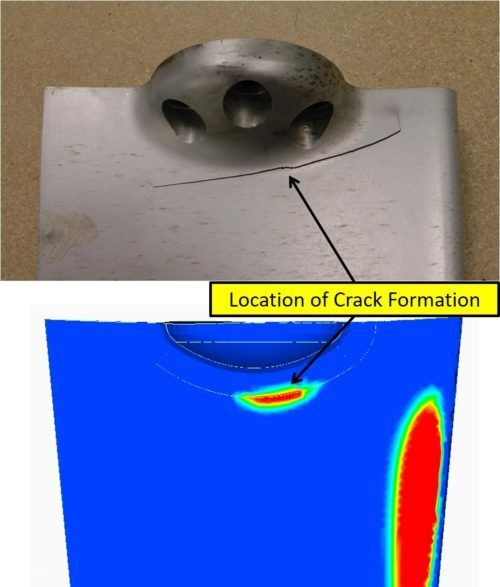

FEA analysis showed excellent correlation between calculated stresses and visual inspection of the blades. This particular blade did not fail; however, there is significant damage on both the suction and pressure surfaces, which led to a large crack forming on one side and compressive yielding on the other, as shown in the pictures below.

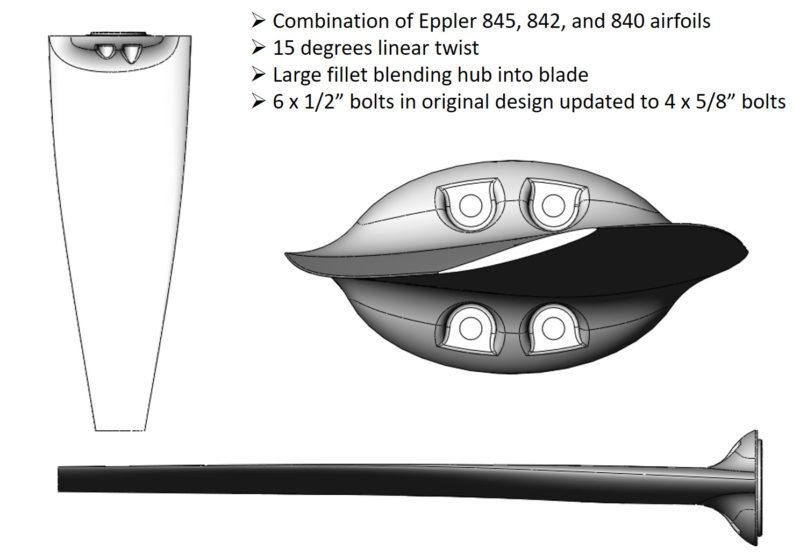

The final redesigned blade geometry is shown below. It was a combination of three different airfoil shapes, which provided a balance between mass distribution, blade stiffness, and aerodynamic efficiency.

If your organization has a challenging structural or aerodynamics challenge, call or email us to find out how we can help. The engineers at Kumair have experience designing a wide variety of aerodynamic components and systems including axial fans, cross-flow fans, propellers, and rotors.