Engineering Design and Analysis

PhD-level engineering support with over 20 years of mechanical and aerospace engineering, carbon fiber composites, and airflow design experience. Consulting is offered through Kumair Consulting.

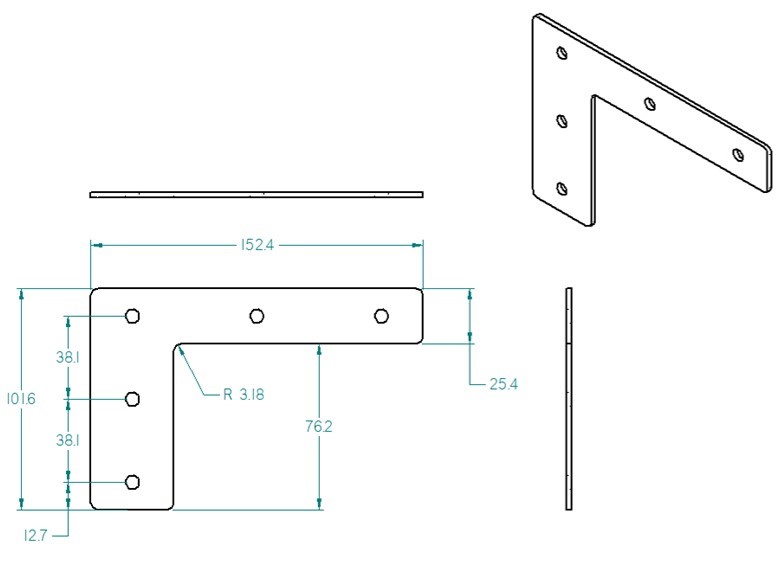

Finite element analysis, or FEA, is used to investigate part and assembly deflection, stresses, and natural frequencies. FEA plays an important role in understanding both the rigidity and failure or an engineered part. Iterative design between CAD, FEA, and computational fluid dynamics (CFD) leads to an optimized design. Kumair Consulting engineers have experience analyzing systems across a wide variety of fields including x-ray imaging, UAV propulsion and aerostructures, industrial automation and robotics, wind turbines, prosthetic feet, military electronics enclosures, and many others.

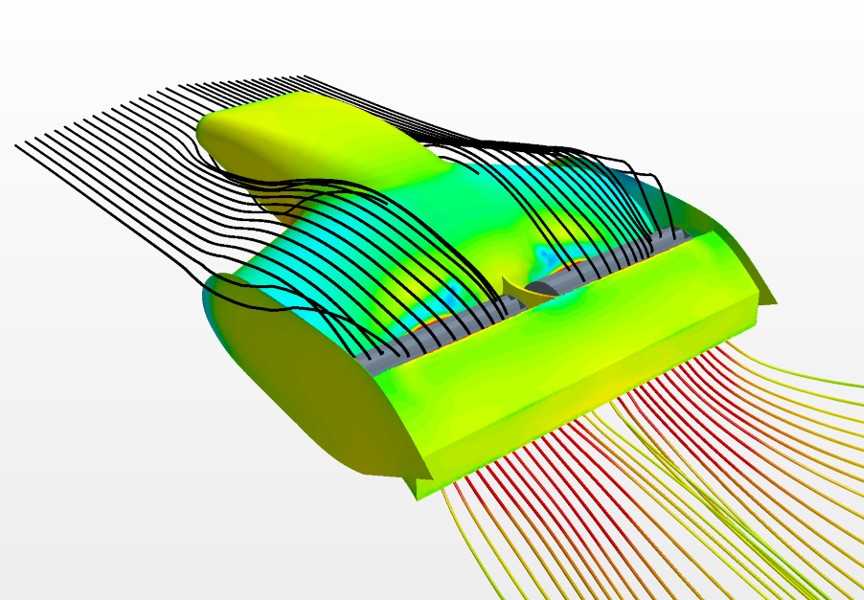

FEA static analysis, FEA modal analysis, and CFD combine to aid the redesign of a 14-foot diameter fan used to power a vertical wind tunnel. Blade failure caused significant damage. Kumair engineers redesigned and managed fabrication of new components that alleviated high stresses due to blade natural frequency excitation.

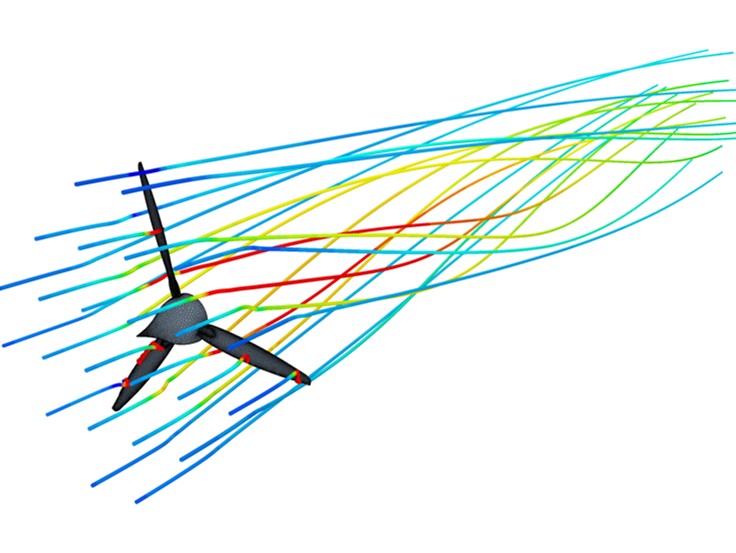

Kumair Consulting utilizes the commercial CFD code Star-CCM+ to help companies, government, and military organizations design a wide range of systems. We have worked on both traditional aerodynamics projects, such as UAV propeller and rotor design, aircraft concepts, transonic propulsion, and wind turbines, as well as more unconventional applications for CFD like waste water treatment, airport runway signs, laser ablation equipment, and personal air purifiers. Having an experienced airflow analyses partner can mean the difference between meeting and missing project deadlines.

Contact Kumair Consulting to discuss your design and analysis project with an engineer. We quote CAD and CFD analysis work on a consulting basis. For projects involving carbon fiber manufacturing, design and analysis, work can often be rolled into the tooling and prototyping costs. Kumair Consulting offers competitive engineering rates with discounts for projects leading to ongoing production. Call or email us for a free consultation.