Carbon Fiber Foam Core

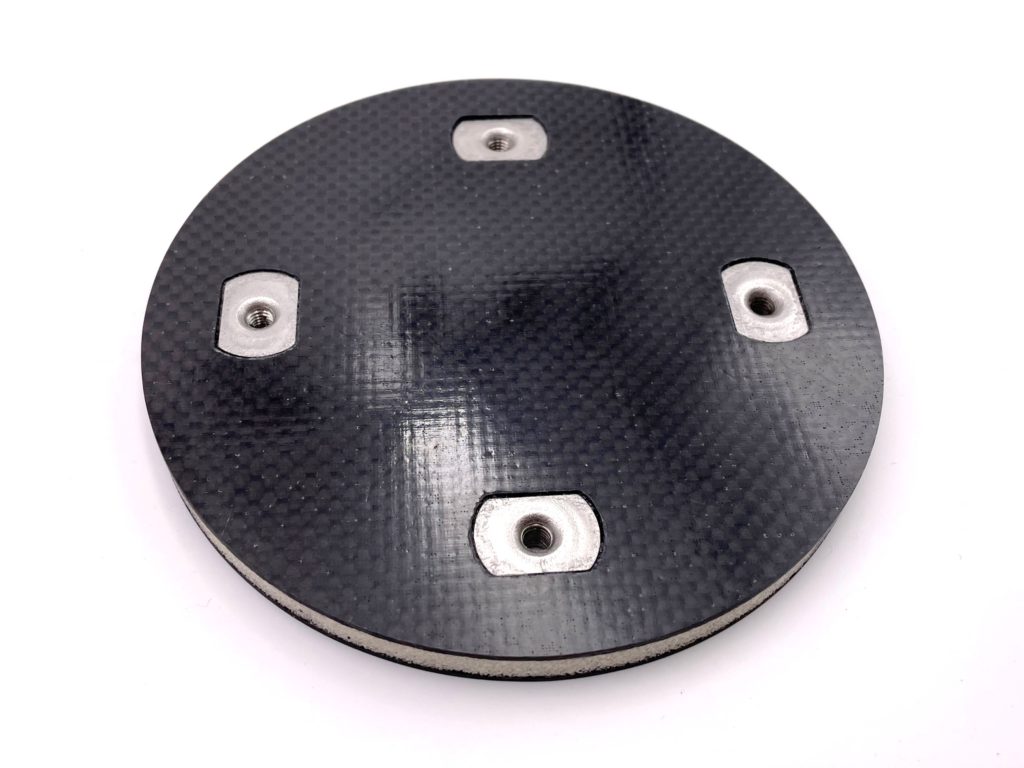

Kumair manufactures carbon fiber sandwich panels with a variety of foam cores. The picture above shows a group of parts made from a laminate with 1/2" LAST-A-FOAM® core and carbon fiber skins comprising both 12K and 3K prepreg to create damage tolerant, high stiffness-to-weight components. The primary benefit of using foam core is to increase the panel rigidity without adding weight, since the high stiffness carbon fiber skins are spaced away from the neutral axis. In addition, foam is more damage tolerant than honeycomb and machines cleanly. Many foams, like the one shown, are also water resistant due to the closed cell construction.

Kumair has the ability to create standard prepreg and high temperature foam core sheets up to 24"x48". Foam cores are available in a variety of densities and thickness ranging from extremely lightweight 1.5 lbs/ft3 to heavy duty 20-30 lbs/ft3 foam, and 1/8" up to 1" thick. This gives the designer tremendous flexibility to optimize a design to meet the given space, stiffness, crush resistance, and temperature requirements.

One of the challenges of designing parts using carbon fiber foam core is integration (i.e. assembly) with other components. Kumair helps customers determine the best way to do this, including CAD design of metal, fiberglass, or carbon fiber inserts and complete system FEA.

Weave Options for Foam Core Carbon Fiber Parts

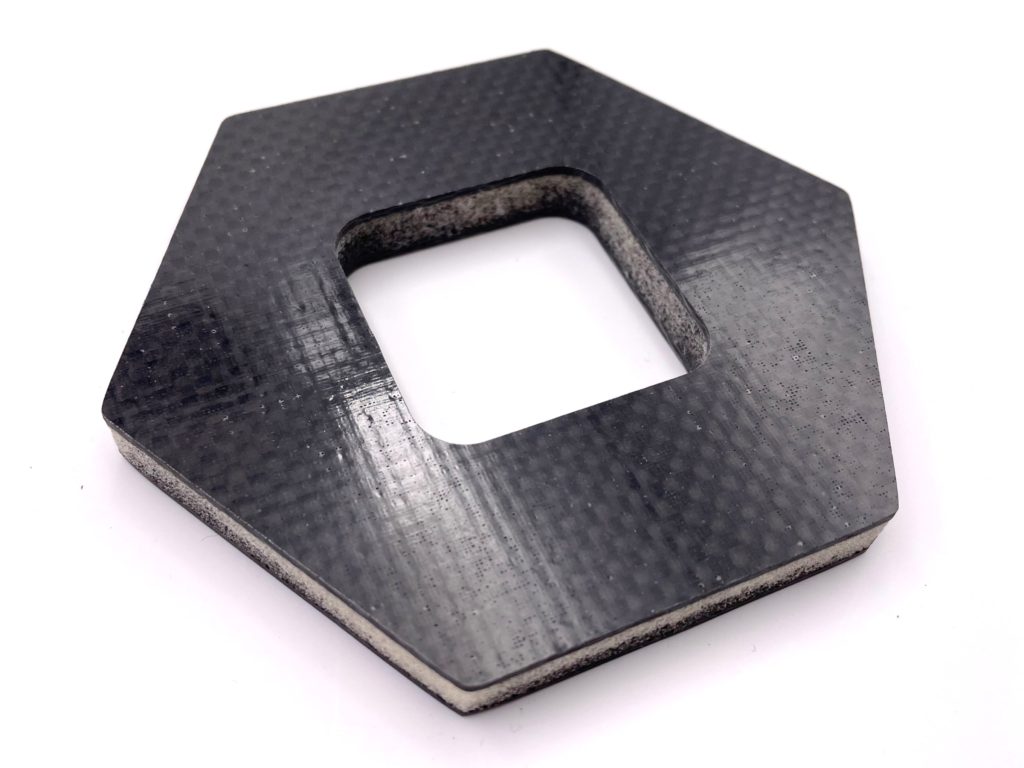

Kumair has the ability to utilize any carbon fiber weave thicknesses and patterns to construct foam core carbon fiber sheets and finished CNC machined parts. Weave patterns include plain, twill, hexagonal, satin, a variety of colors, and hybrid carbon-fiberglass and carbon-Kevlar® options.

Surface Finish Options

Kumair carbon fiber foam core sheets can be manufactured with a variety of surface finishes. Our standard pressed finish is a semi-gloss pinhole free finish. Spray clear satin finishes are also available, and are both attractive and durable. If your parts will be bonded to other components, a sanded finish is typically the best option. Kumair works with customers to determine the best approach for the specific application.

If your project requires lightweight, high stiffness-to-weight ratio material, carbon fiber foam core may be a good fit. Call or email us today to speak with an experienced composites engineer. Work with our team to develop a solution that meets the challenging requirements for your x-ray imaging, automation, electronics enclosure, or any other application.