Carbon Fiber Prepreg

Kumair is a proud distributor of US-manufactured APCM prepregs. Kumair supplies a wide range of carbon fiber and fiberglass prepreg materials for companies manufacturing their own composite parts. Our engineers can help you design your parts and assemblies, and then we can do the manufacturing or help you select the best prepregs to do the fabrication in-house.

As a leader in custom prepregs, APCM has built a reputation for making high quality materials that yield consistent results. As a sales representative and distributor for APCM, Kumair offers a complete composites design and manufacturing option where we can help you from start to finish in the process. An overview of several standard carbon fiber prepreg options are given below; however, we also work with customers to develop highly optimized prepreg solutions for their specific application.

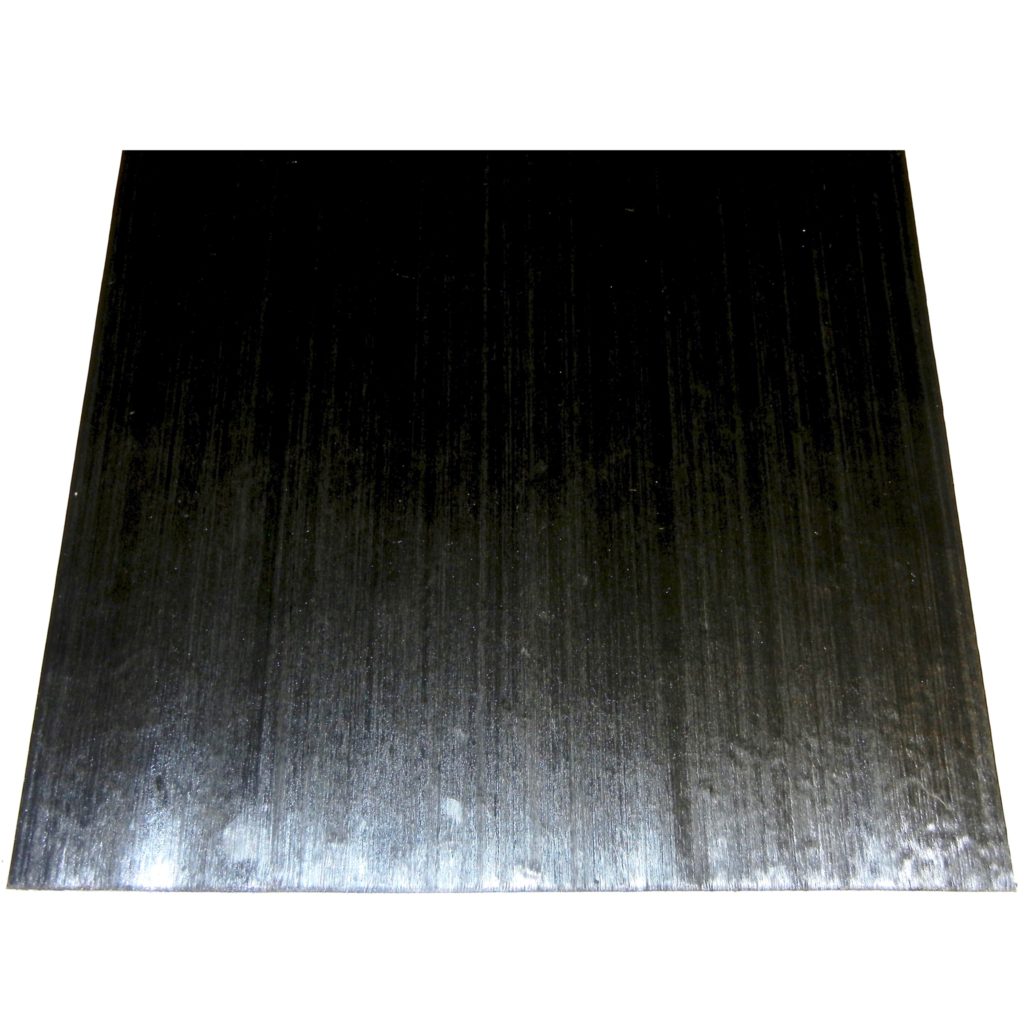

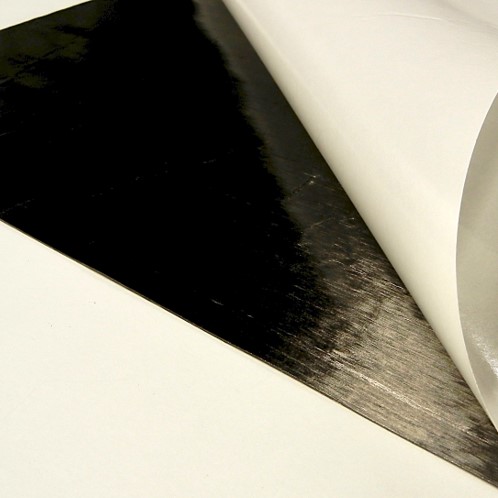

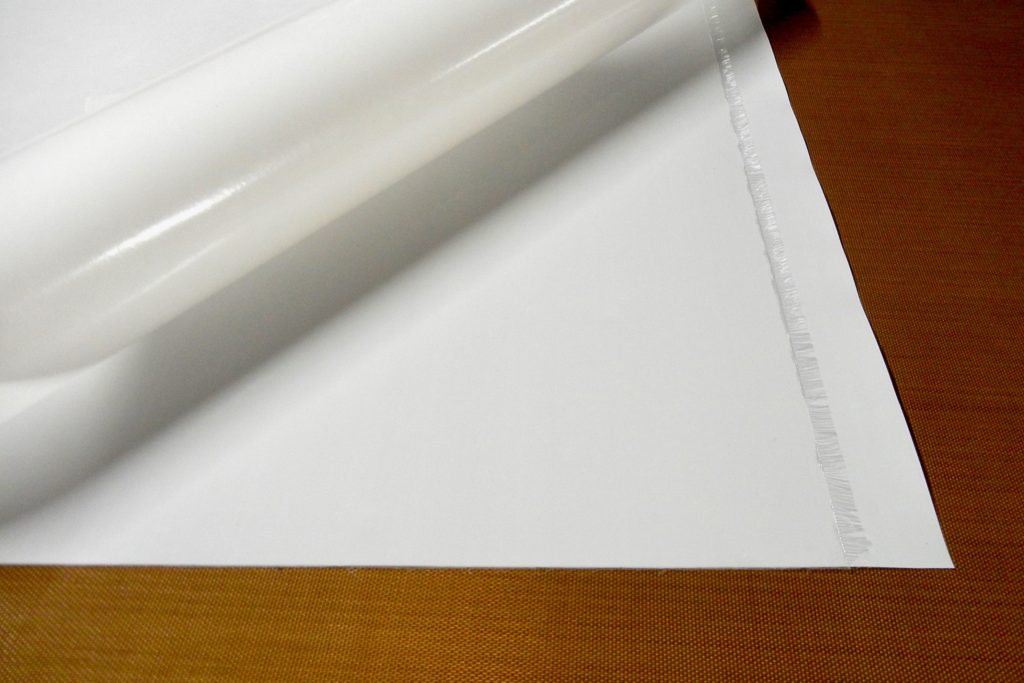

Uni-Directional Carbon Fiber Prepreg

Uni-directional, or Uni, prepreg provides the greatest flexibility in fiber orientation. With the fibers aligned along the direction of the roll, continuous fibers are available for longer parts. By cutting and orienting the fibers along 0/90 deg axes or off-axes (for example, +/- 45 deg), one can create a quasi-isotropic laminate as small or large as you need. Uni carbon fiber prepregs offer the highest stiffness-to-weight ratio and the ability to tailor the stiffness along different axes by placing a greater percentage of the fibers along one axis versus an orthogonal one. Our uni-directional prepreg is typically sold in 50 yard rolls and widths ranging from 6” up to 20”. Fiber weights and resin content can easily be tailored to meet your needs, with the heaviest uni-directional carbon fiber prepreg being 600gsm, which builds up quickly to reduce labor costs when making thick carbon fiber plates and tubes.

APCM uni-directional carbon fiber prepreg is the ideal material for x-ray imaging applications, since it is 100% fiber and resin with no other binder materials. Kumair has successfully implemented this material into a variety of x-ray imaging parts with excellent results. Uni carbon fiber prepreg typically has the lowest x-ray attenuation and eliminates image weave visibility, particularly for thicker laminates.

Visit our Kumair Composites Shop for pricing and to place an order for our uni-directional carbon fiber prepreg.

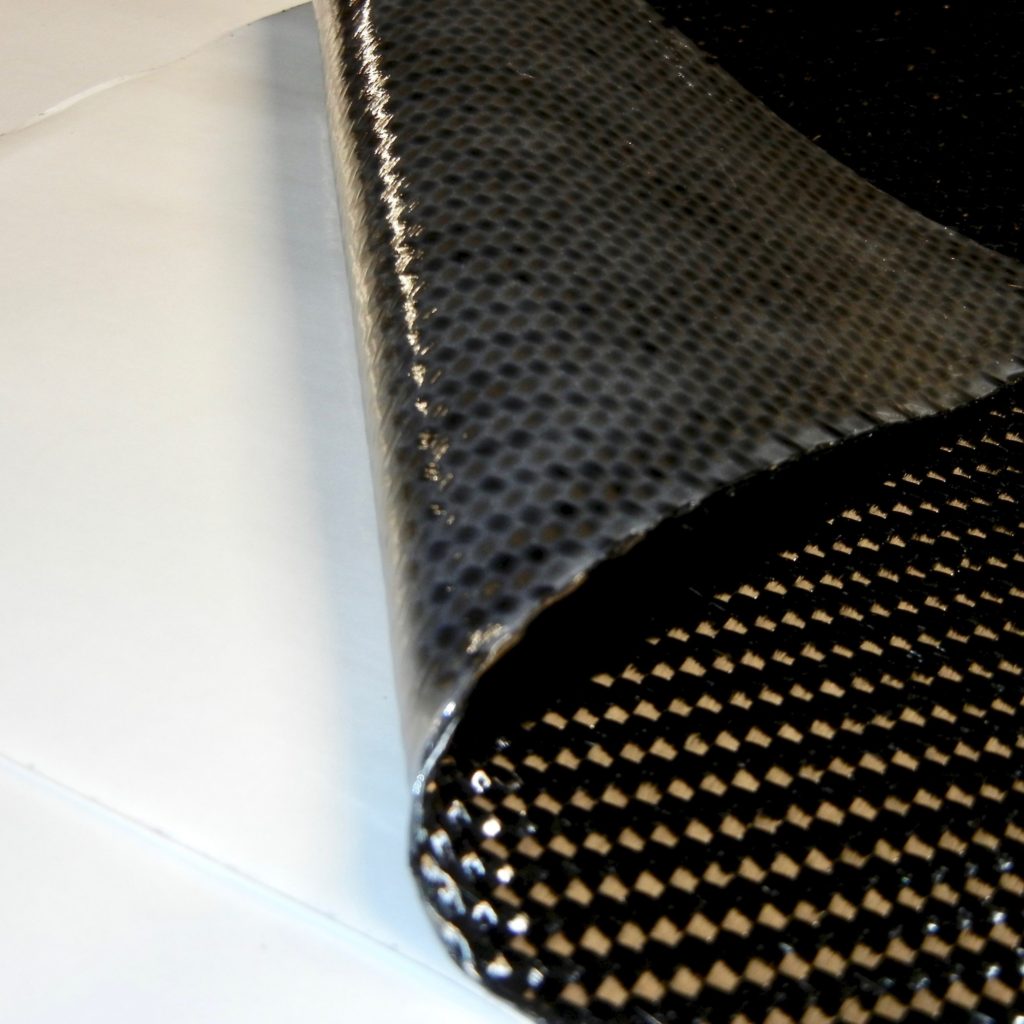

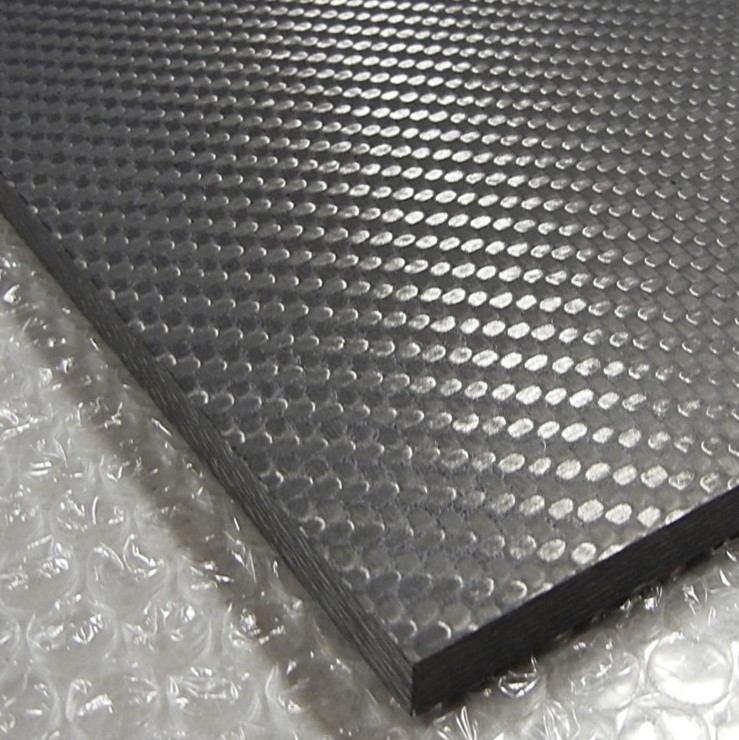

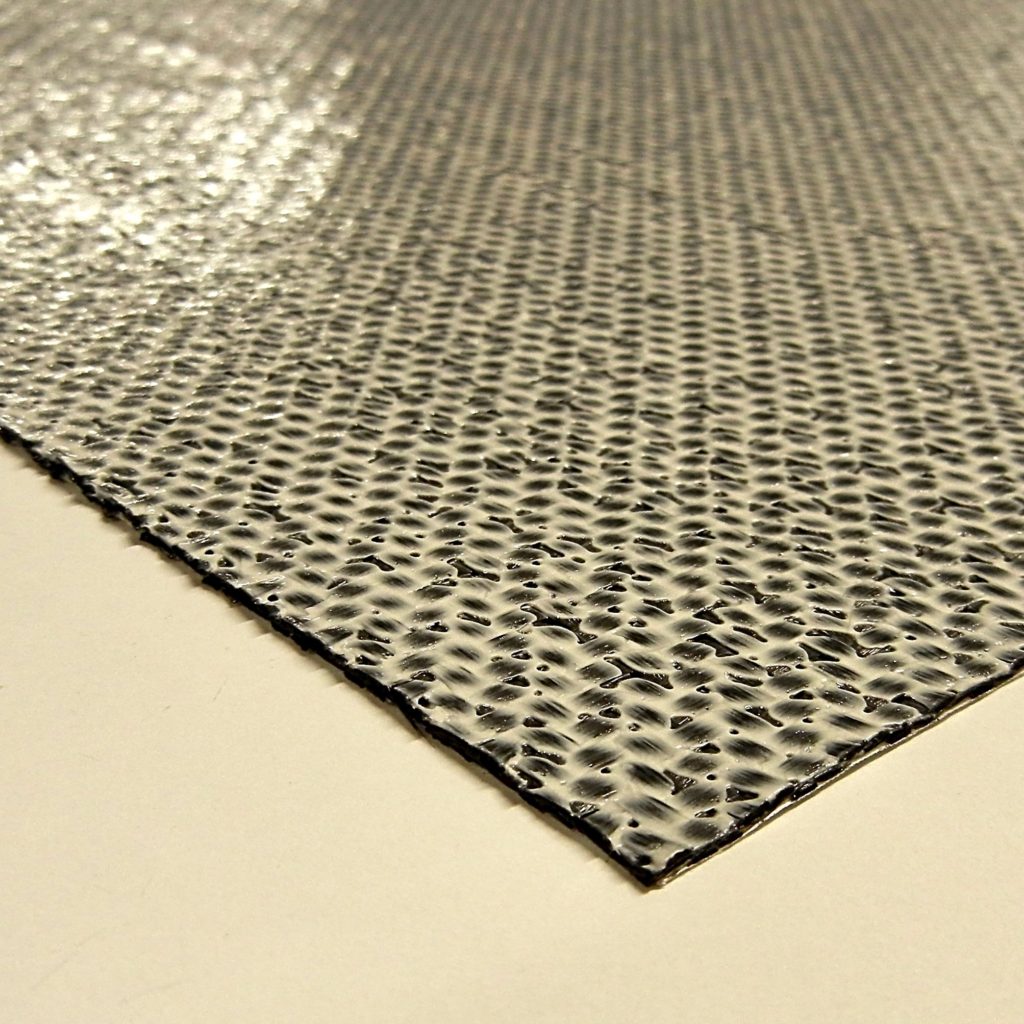

Woven Carbon Fiber Prepreg

Woven carbon fiber prepreg is used both for aesthetics and durability. Whereas uni-directional prepreg offers a higher stiffness-to-weight ratio, woven prepregs are typically more damage tolerant. Often, the best option is a combination of uni-directional composite material in the core of a laminate and woven prepreg face plies (or skins). This gives the finished part the carbon fiber look many people want while also reducing the changes a splitting or fiber tow pull-out during machining or while the part undergoes localized stresses (for example, during an impact). For higher impact resistance, or when there are many holes or other small features, an all-woven prepreg layup schedule may be the best option.

Woven carbon fiber prepreg is available in a variety of weights, aesthetic weaves, and resin content. Fabrics weights range from lightweight 1k and 3k weaves up to heavy 12K twill that lays up at 0.025" per ply. We carry many standard options in woven prepregs, but Kumair also works with customers to develop custom solutions. One of the advantages of working with Kumair and APCM is that minimum order quantities are low for prototyping purposes, with many materials available in rolls as small as 10 yards.

Visit our Kumair Composites Shop for pricing and to place an order for woven carbon fiber prepreg.

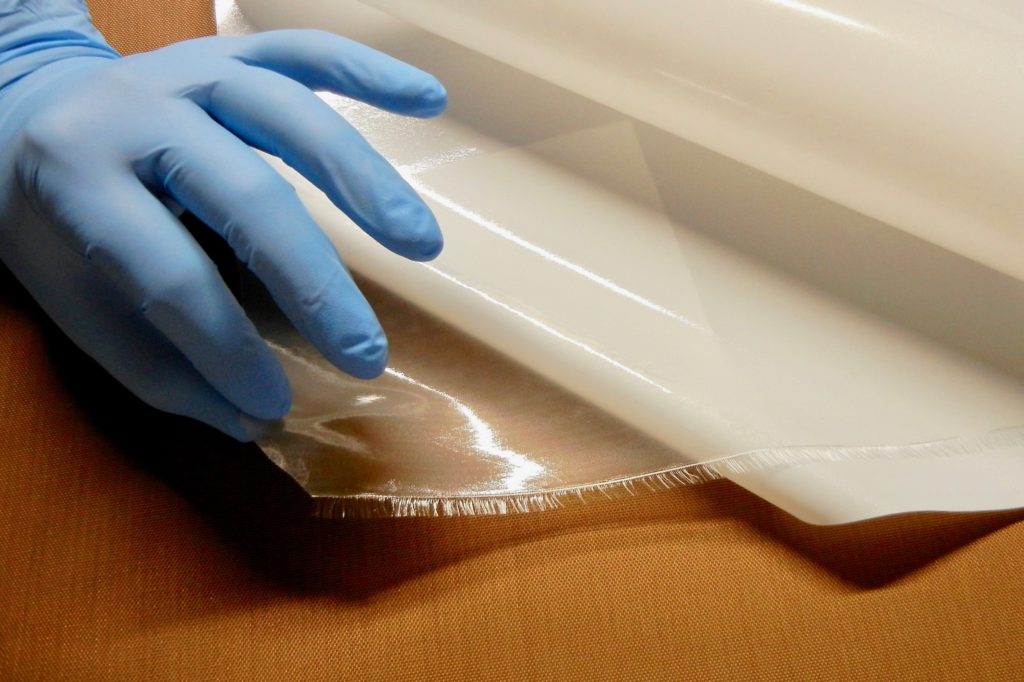

Fiberglass Prepreg

In addition to carbon fiber prepreg, Kumair also offers APCM fiberglass prepreg. Fiberglass prepreg is lower cost than carbon fiber, but also is necessary for some applications, for example if an antenna is enclosed within the structure. Carbon fiber attenuates radio waves, thus making it necessary to move to fiberglass, aramid (Kevlar®), or another composite fiber reinforcement. This is common in radome design. For use in surfacing carbon fiber parts, Kumair sells an ultra-thin 19 gsm woven fiberglass prepreg that is perfect for eliminating pinholes. It can also be used for skinning lightweight core materials to create some of the lightest composite parts possible.

If your application requires high volumes of fiberglass prepreg, APCM material may be a great option. Low cost, consistent fiberglass prepreg made in the United States is sometimes challenging to source. Our capacity to make runs of thousands of yards and also offer great customer service is somewhat unique in the industry.

Flame Retardant Carbon Fiber Prepreg

Flame retardant prepregs use specially formulated resins that self-extinguish when a flame is applied to the part and then removed. APCM has developed a proprietary flame retardant resin system that is ideal for making low weight flat sheets or molded components that meet FAR 25.863(a) Appendix F vertical burn testing. Click here for test data produced for 1/8” woven carbon fiber samples. This particular laminate easily passed vertical burn testing.

If your application is in aircraft interiors or any other industry that requires material flame retardancy, our flame retardant prepreg may be an excellent option. We have the ability to prototype small quantities, then ramp up to high volume production, whether it is thousands of pounds of uni prepreg or thousands of yards of fiberglass and carbon fiber woven prepregs.

Visit our Kumair Composites Shop for pricing and to place orders for flame retardant carbon fiber prepreg.

Material and Weave Options for Prepregs

Carbon fiber, fiberglass, aramid, and other composite reinforcements are available in a wide variety of weave patterns and weights, with just about any combination possible to prepreg. Common weave patterns include plain weave, twill weave, and harness satin, although there are many other exotic weave patterns, with most offers only aesthetic differences and no actual improvement to manufacturing or strength. Uni-directional is non-woven material where all of the fibers are aligned in the same direction, offering great flexibility of design and fabrication, but at the tradeoff of extra labor (to cut and lay down plies at different orientations). Also, uni-directional often cannot make thin laminates well, since a minimum thickness is usually required to provide enough plies to have fibers in multiple directions and also create a well-balanced layup schedule. Kumair and APCM work with customers to identify the best weave and material options both from a performance and cost perspective.

Call or email us today to speak with an experienced composites engineer and for prepreg quotes.