Carbon Fiber Metrology and Scientific Equipment

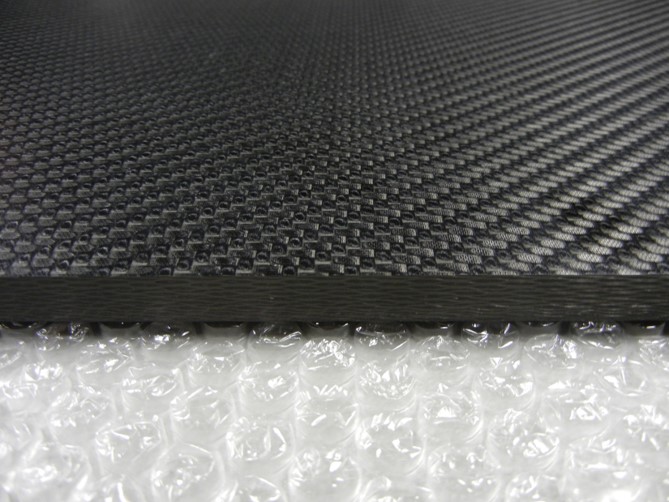

Due to its low coefficient of thermal expansion (CTE), carbon fiber is an ideal material for many metrology and scientific equipment applications. One of the challenges in metrology is susceptibility to environment changes, in particular temperature variation. In an aluminum structure, for example a target or laser tracker, the high CTE can cause problems if the ambient temperature varies too much. This is especially true for measurements made outside in very cold or very hot environments. Carbon fiber has an extremely low CTE – on the order of 1.5 x 10-6 per degree C for an all-woven carbon fiber laminate, which is similar to that of Invar steel. Further CTE reduction is possible through fiber biasing, whereby uni-directional carbon fiber plies are aligned such that a greater percentage are in the longitudinal direction than the orthogonal direction. This provides a means to reach CTE values below 10-6 / deg C. In fact, by using special ultra high modulus pitch carbon fibers it is possible to achieve close to zero (or in some cases negative) CTE in the direction of the fibers.

Carbon fiber metrology equipment also have the benefits of high stiffness and low mass, which means much higher natural frequency than comparable metal mounting plates, tubes, or other assemblies. High natural frequency often makes isolation of carbon fiber structures easier, for example through the use of resilient mounts. The low mass also offers reduced weight, which is important for portable systems.

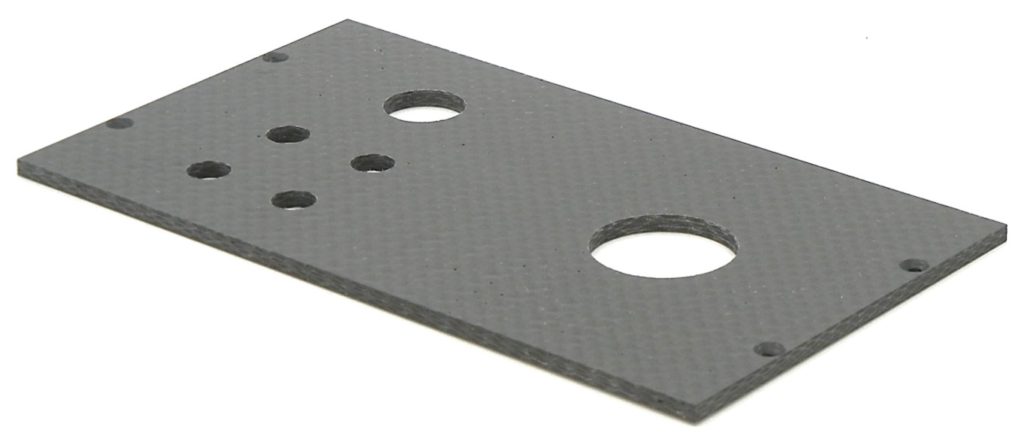

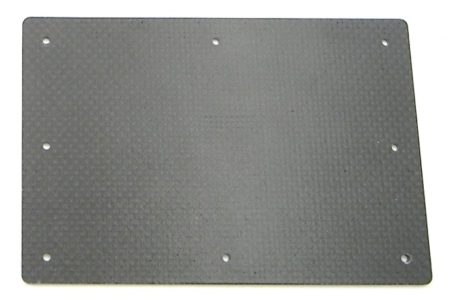

The engineers at Kumair have many years of experience working with metrology and scientific equipment manufacturers to develop custom carbon fiber parts and assemblies. Kumair has the ability to fabricate extremely thick carbon fiber mounting plates up to 1” or greater, which provide unparalleled thermal stability and stiffness to weight ratio. Example of applications include telescope lens support structures and mounting plates for lasers and mirrors.

Kumair can work with your engineering team to develop an optimized carbon fiber solution for your project. Kumair offers CAD, FEA and CFD analysis, and full carbon fiber fabrication and CNC machining services. Contact us to see how we can help.