Carbon Fiber Sheets and Plates

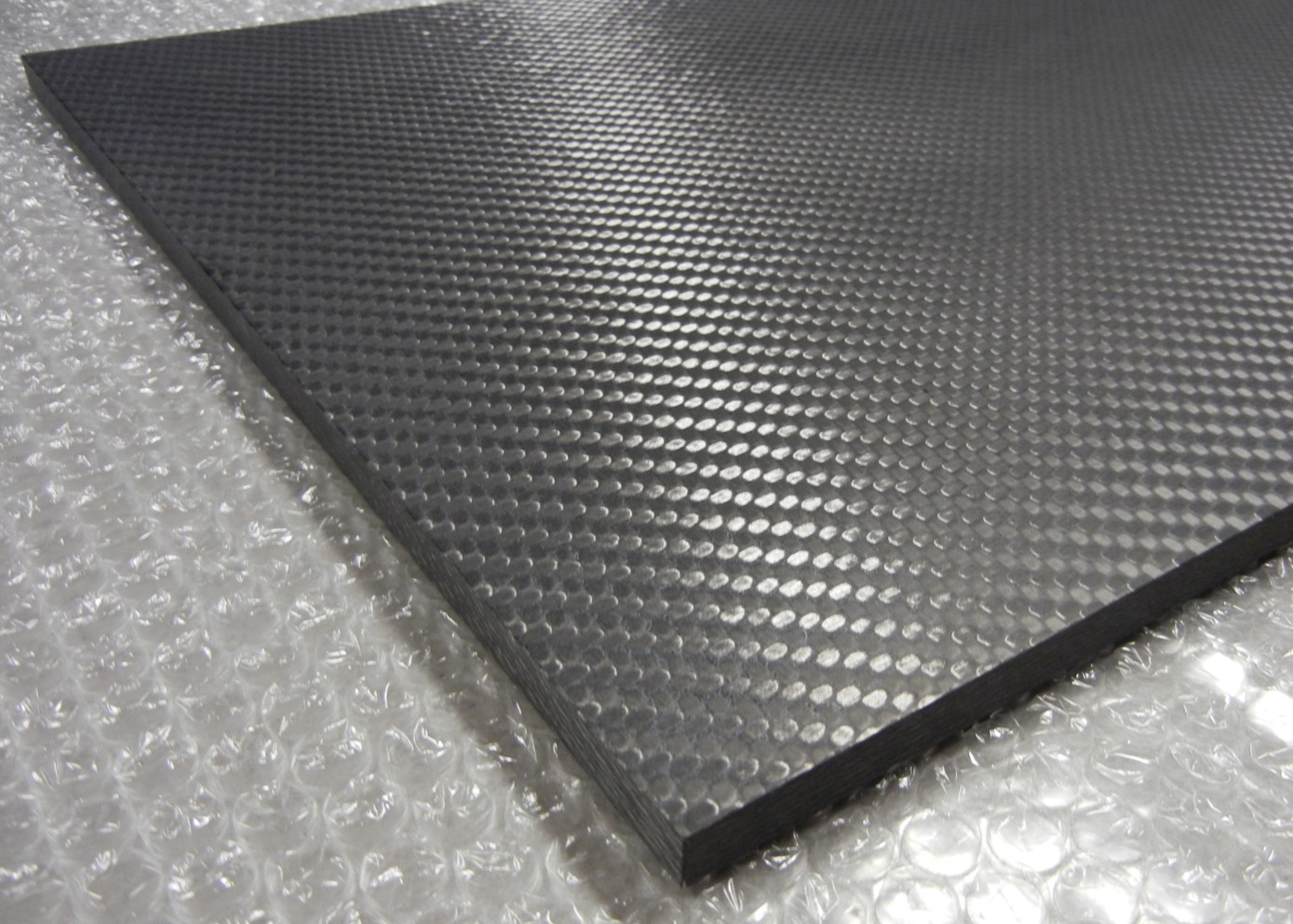

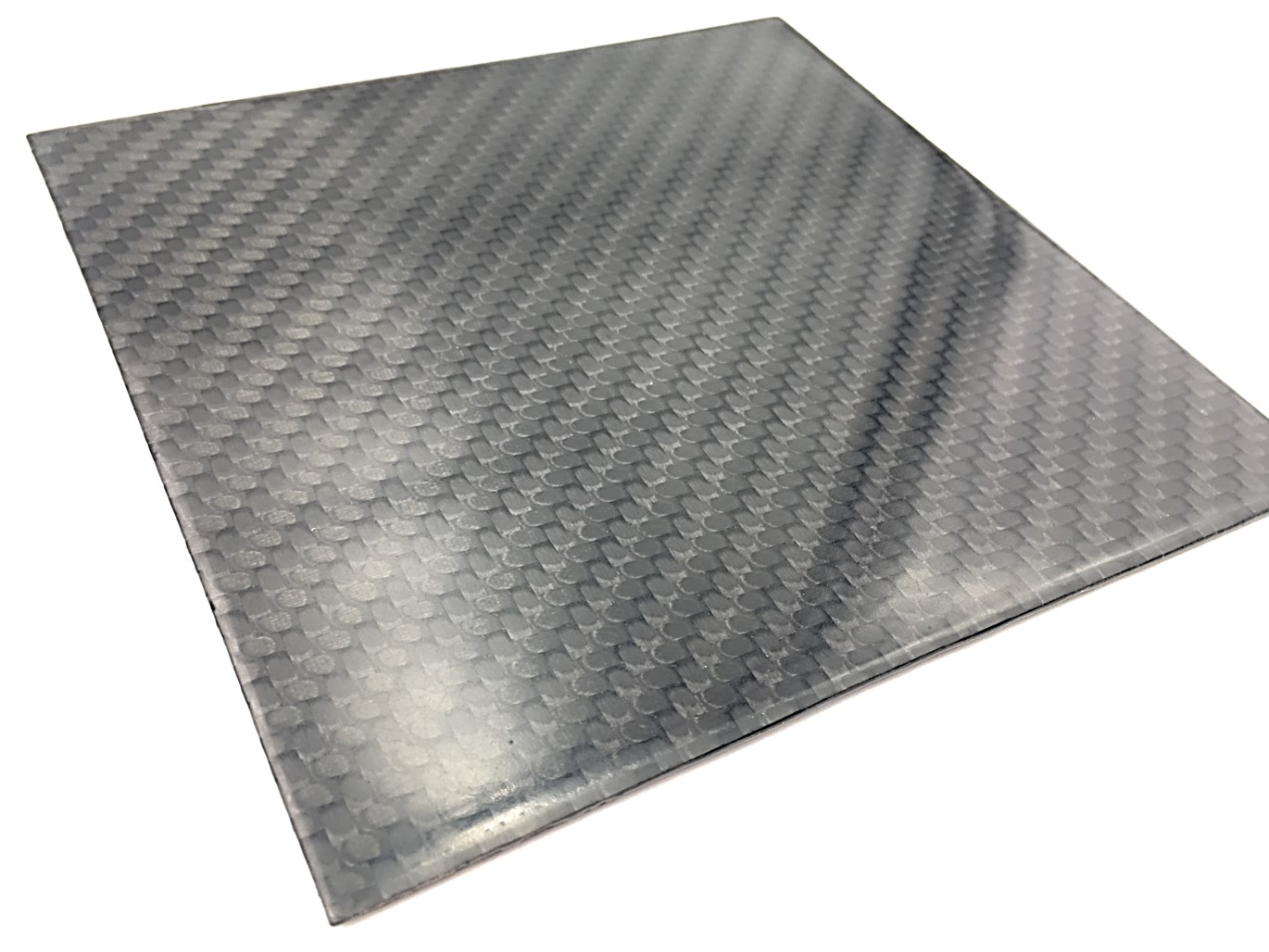

Kumair solid carbon fiber sheets and plates are produced for a wide variety of applications. Thickness ranges from thin veneer up to 1.5” thick plates. Kumair utilizes prepreg carbon fiber for sheets and plates to maximum the mechanical properties. Carbon fiber sheets and plates made from prepreg are typically about 30% more rigid than those made by a wet layup or vacuum bagging process, since the fiber to resin ratio is higher. And since pressed prepreg carbon fiber sheets have minimal voids and straighter fibers, the strength is also higher than non-prepreg options.

Weave Options for Carbon Fiber Sheets and Plates

Kumair works with customers to optimize carbon fiber sheets and plates to maximize the benefits of the carbon fiber composite material properties. For example, all-woven carbon fiber plates (all plain weave or twill, for example) provide excellent machinability and greater damage tolerance. Also, all-woven carbon fiber means that the weave pattern will always be present, even on edges and 3-dimensional sculpted surfaces. This type of composite is often used for the best aesthetics and design flexibility for heavily machined parts.

By incorporating uni-directional carbon fiber into the laminate, the stiffness and strength of the carbon fiber plate can be tailored to match the applied loading constraints. For example, if the component is primarily used in bending about a single axis, aligning additional uni carbon fiber in one direction will often result in a much lighter part. Likewise, if the part is primarily in torsion or has off-axis bending, then fibers can be oriented at +/- 45 degrees, which maximizes the torsional rigidity.

Surface Finish Options and Applied Designs

Kumair offers several different surface finish options for carbon fiber sheets. These include matte/satin finish, sanded finish, and gloss. All of our finishes are applied after molding is complete. As a result, our matte and gloss finishes are much more durable than “off-the-tool” thin gloss finishes, often typical of vacuum bagged carbon fiber sheets. In addition, Kumair has the ability to apply single and multi-colored vinyl designs to most carbon fiber flat components. A clear coat surface finish is then applied over the vinyl, protecting the artwork or lettering and giving a 3-dimensional effect.

CNC Cutting of Carbon Fiber Sheets and Plates

Kumair specializes in medium to high volume CNC cutting of carbon fiber sheets and plates. If you have a project that requires a United States based manufacturer of carbon fiber flat material and CNC machining, we can help. Kumair has the ability to customize any layup to optimize for your application, then cut to match your CAD model. Whereas most composite companies only work with standard layup schedules, for example, 0/90 and 45 deg ply quasi-isotropic, Kumair specializes in more complex laminates often used in high performance applications. From simple 2D CNC machining to complex 3D profiles, we offer expert engineering, great turn-around, competitive pricing, and turn-key support and ramp-up to volume production.

Call or email us today to speak with an experienced composites engineer about our solid carbon fiber sheets and plates. Our team goes well beyond the typical carbon fiber fabrication shop with full engineering support, including CAD, composites design, and aerodynamics analysis. Send us your drawings for a free, no-obligation project analysis and quote for finished CNC machined carbon fiber parts or assemblies.