CFD Analysis of Wastewater Treatment Density Current Baffles

Municipalities are required to maintain high water quality. When populations expand, however, this puts a strain on the wastewater treatment facilities. One option is to build additional clarifier tanks, but this costs millions of dollars. An alternative is to strategically place fiberglass baffles within the clarifier tanks to help improve the particle settling efficiency. Kumair president Dr. Joe Kummer worked with Fiberglass Fabricators, Inc. of Smithfield, Rhode Island to analyze the effect of various density current baffle geometries on the settling efficiency of particles within wastewater treatment clarifier tanks. The findings helped to optimize baffle location and shape, and led to improved understanding of the fundamental physics of this complex problem. More information about this product is available on the Fiberglass Fabricators website.

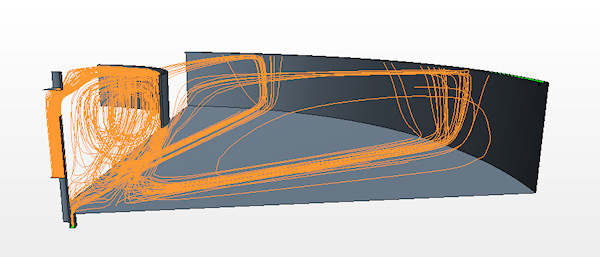

CAD modeling was done in Solidworks and CFD analyses in Star-CCM+. For the case shown, the calculation is full 3D. Particles were introduced into the water to simulate the actual distribution of different particulate sizes. As expected, larger particles quickly sink to the bottle of the tank, whereas smaller particles remain suspended much longer. Current density baffles cause smaller particles to remain in the core flow of the tank for extended periods, allowing them time to settle, and thus greatly increasing the efficiency of the tank.

If your organization requires fluid dynamics analysis including particulates, Kumair engineers have experience in this area. If you think we can help with your project, email us through our contact page. Kumair can offer a no cost, no obligation evaluation of your project.