For projects requiring higher operating temperatures than standard carbon fiber parts can offer, Kumair makes high temperature carbon fiber capable of 500F and higher. Testing has shown that rigidity is maintained to over 500F. The picture below was taken after 30 minutes at over 500F (with a max testing temperature of 525F in this case). Short durations at even higher temperatures are possible with this material.

High Temperature Carbon Fiber Manufacturing

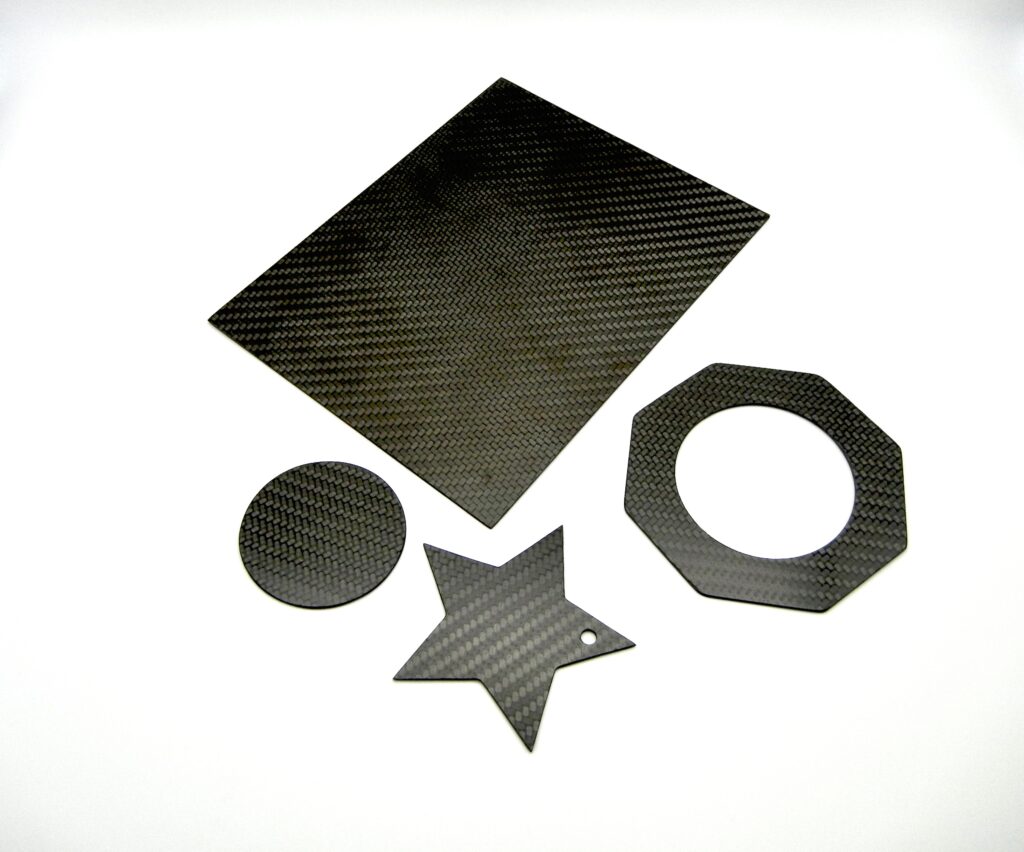

Kumair uses a custom-built hydrualic platen press to make high temperature carbon fiber sheets. Processing the material at surface pressures 20 times greater than vacuum bagging results in much higher fiber to resin ratio, low voids, and excellent surface finish. Kumair has the ability to utilize most carbon fiber weaves, thicknesses, and patterns to construct high temperature carbon fiber sheets.

Surface Finish Options and Applied Designs

Kumair offers standard pressed, gloss, and sanded finishes, for high temperature carbon fiber components.

CNC Cutting of High Temperature Carbon Fiber

Kumair works with customers to develop custom high temperature carbon fiber components and assemblies. For customers requiring CNC work, Kumair has the ability to CNC cut high temperature sheets and molded parts.

Call or email us today to speak with a composites engineer about our high temperature carbon fiber sheets and custom molded parts. If your project requires temperatures in excess of what standard carbon fiber laminates can offer, work with our team to design and manufacture something that meets your needs.