CFD

Projects and Examples Utilizing CFD

Computational Fluid Dynamics, or CFD, is used across a myriad of industries and applications to better understand, design, and optimize systems that involve fluids. CFD now finds uses ranging from aircraft and fan design to wastewater treatment particle setting tanks to the flow of plastics in an injection molding process. This webpage serves as a knowledge base for many past projects and CFD test cases worked on by Kumair engineers. Since the primary focus at Kumair is carbon fiber composites, we only take a limited number of CFD consulting clients every year. If your organization has an airflow challenge do not hesitate to reach out to us.

Analysis of Density Current Baffles

Density current baffles, typically manufactured out of fiberglass, significantly improve the settling efficiency of wastewater treatment clarifier tanks. CFD analyses helped Fiberglass Fabricators, Inc to optimize their design, giving them a clear advantage in the marketplace.

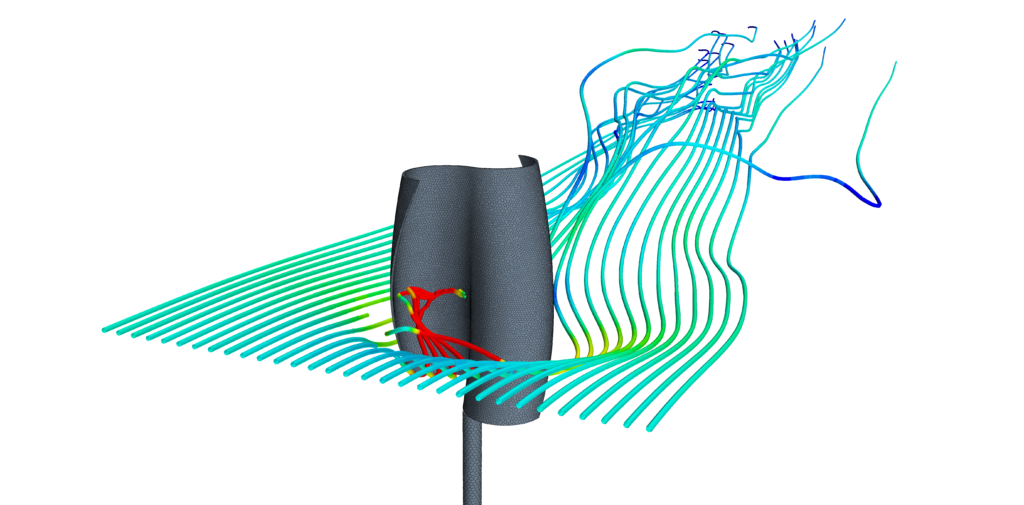

Savonius Wind Turbine Design and Analysis

Read about a unique Savonius vertical axis wind turbine designed by Kumair engineers. As a drag-based turbine, this type of machine can be implemented across a wide range of applications and climate conditions.

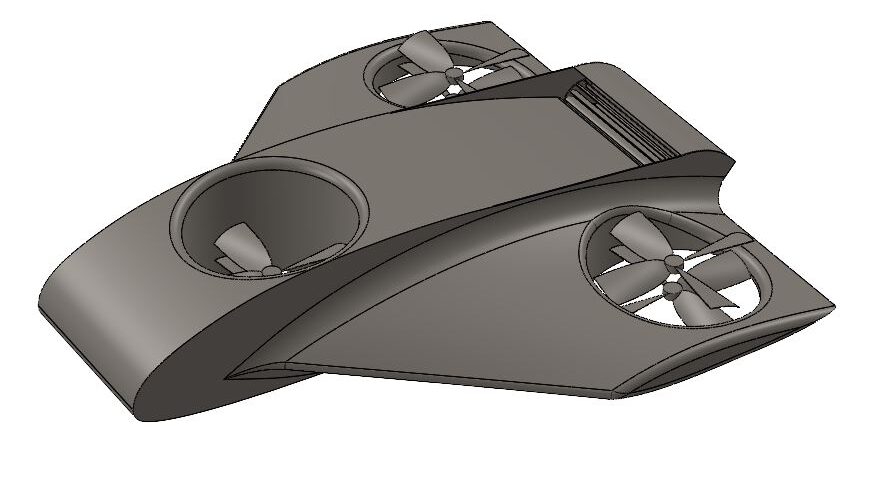

Cross-flow fan propulsion offers several unique capabilities when compared with other aircraft configurations.

Hybrid Axial and Cross-Flow Fan Propulsion for Transonic Blended Wing Body Aircraft

Funded through a NASA SBIR contract, Kumair engineers investigated the application of Propulsive Wing cross-flow fan technology to a transonic blended wing body aircraft. The results of this study showed the potential for a dual axial and cross-flow fan propulsion system, whereby the cross-flow fan ingests the highly non-uniform boundary layer flow near the surface of the wing-shaped body, yielding a much more uniform inflow for the axial fan, thus improving overall system efficiency.

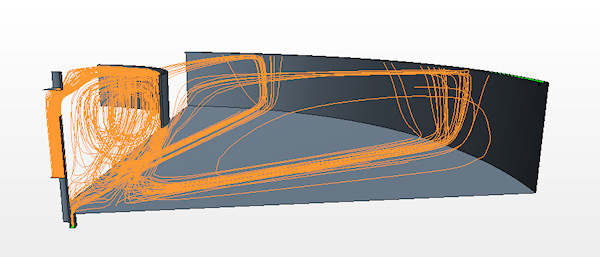

Redesign of a Large Vertical Wind Tunnel Axial Fan

Appalachian Amusement Center operates a large wind tunnel used for sky diving training. The primary fan for the tunnel measures 14 feet in diameter and accelerates air to over 130 mph. Kumair engineers worked with Appalachian Amusement to upgrade the fan with a new blade design.

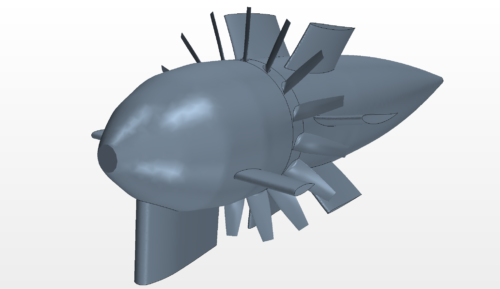

The Personal Breeze air purifier system utilizes the naturally buoyant air rising around an individual to create a small area of cleaned air in the breathing zone. By drawing in air as it rises, filtering it, and gently blowing it back toward the user such that it is entrained into the thermal plume, the Personal Breeze is able to filter the air an individual breaths while consuming under two Watts of power.