Carbon Fiber Composites Manufacturing

Whether your organization requires CNC machining of a small number of parts or a large production run, Kumair has the experience to work with you from concept through final delivery of the carbon fiber composites parts and assemblies. Carbon fiber manufacturing begins with a thorough understanding of the project requirements. Very often, the design goal is simply to reduce weight; however, there are many other benefits to integrating carbon fiber into a design, such as low thermal expansion and resistance to yielding.

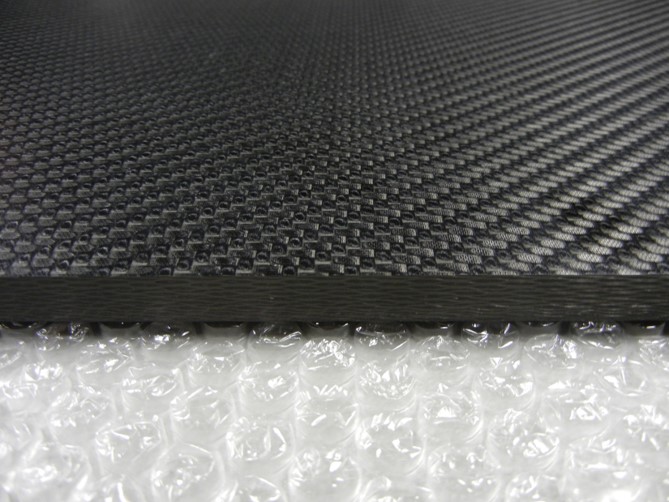

Solid Carbon Fiber Composites

In a standard carbon fiber composite part, such as a sheet, tube, angle, stiffener, or even complex molded shape, the thickness comprises many layers, or plies, of thin material. Depending on the application, the individual carbon fiber plies may be uni-directional (i.e. all of the fibers align in a single direction) or multi-directional (for example, stitched uni or woven). The most common multi-directional plies are woven, whereby 50% of the fibers are aligned in the longitudinal direction and the other 50% of the fibers in the lateral direction. In this way, individual plies are placed on top of one another, building up a final carbon fiber part with fibers in two directions. This type of composite is called orthotropic, and will have maximum strength along the direction of the fibers (in this case the 0o and 90o directions, termed a 0/90 laminate), but less strength along any off-axis direction (for example, the 45o axis). For a given application, if the composite part is expected to see off-axis bending or torsional loads, fibers should be placed along off-axis directions. Such laminates are termed quasi-isotropic, since they start to approach the uniform (or isotropic) properties of a homogeneous material, such as non-fiber reinforced plastic or metal.

At half the weight of aluminum, carbon fiber parts provide a great alternate to metal in many instances where portability, low thermal expansion, and resistance to yielding are major design drivers. For example, a carbon fiber part can typically bend almost up to the point of fracture without any yielding (i.e. permanent deformation). In applications where large elastic deflections with minimal energy loss is important, carbon fiber is often the best option. The challenge, of course, is designing and manufacturing such a part, since this takes greater engineering and fabrication expertise than for an equivalent metal part or assembly.

The engineers at Kumair have experience designing and manufacturing hundreds of carbon fiber parts and assemblies ranging from unmanned vehicle frames and rotors to industrial automation to x-ray imaging panels. In addition, fiberglass, Kevlar, lightweight cores, and other more exotic plies can be introduced into the composite to design a truly optimized system. Solid carbon fiber panels can be manufactured as thin as 0.003” or up to several inches thick.

Metal Core Composites

At Kumair we have also developed techniques for including metal cores into carbon fiber parts. Traditionally, sandwich core carbon fiber sheets (and CNC machining parts from them) utilize a lighter-than-carbon (LTC) material, such as foam or honeycomb. This creates an ultra lightweight panel with high rigidity, structurally similar to an I-Beam. By contrast, one can use a heavier-than-carbon (HTC) material, such as magnesium or titanium to achieve very different material characteristics. HTC materials yield a carbon fiber sandwich panel that has high impact strength, nearly isotropic bending properties, and excellent machinability.

One of the challenges with solid carbon fiber or LTC materials is the difficulty machining threaded holes and countersinks. Solid carbon fiber, foam core, and honeycomb core perform very poorly when threaded or machined to thin edges, for example when machining countersinks. As a brittle material (i.e. little to no yielding), carbon fiber will deform elastically almost up to the failure stress. This translates into an inherent weakness with respect to holes and countersinks (i.e. weak threads that are easily stripped and countersink edges that crack under relatively low bearing loads). Many carbon fiber composite designs cannot include HTC materials, such as magnesium, aluminum, titanium, or steel, in which case there are many techniques for overcoming this. Or possibly the design can only include metal at specific locations. This is also easily accommodated. However, a new option developed by Kumair integrates metal cores into carbon fiber sheets and assemblies, and offers a new dimension to carbon fiber design.

Magnesium Core Carbon Fiber

Magnesium is only about 20% heavier than carbon fiber, and significantly lighter than aluminum. By using magnesium as a core material, it is possible to achieve a metal core composite that is only slightly heavier than a solid carbon fiber part (a carbon fiber sheet, for example), yet has much higher impact and fracture toughness. The largest benefit of magnesium core comes in the form of clean holes and countersinks, and strong threads. Carbon fiber cannot be threaded, since the strength of the threads would be no greater than the matrix, typically cured epoxy, vinyl ester, or phenolic resin. Threaded carbon fiber sheets, tubes, or molded parts will strip under even light bolt torque. The primary option for overcoming this is to use flanged inserts, threaded bushings, or similar metal inserts. The metal insert takes all of the localized load from the pin or bolt, and the stresses are transferred to the carbon fiber parts via a bonded joint with sufficient contact surface area. By contrast, a magnesium core part can be drilled and threaded in the same way a solid metal part is. Also, countersinks in a magnesium core carbon fiber part are much stronger than solid carbon fiber without a metal core.

Titanium Core Carbon Fiber

Titanium is heavier than aluminum, yet lighter than steel. Titanium has a high strength to weight ratio, low thermal expansion, and is typically very corrosion resistant. As a result, it is a good match for carbon fiber. Like with the magnesium core carbon fiber parts described above, titanium core carbon fiber has the same benefits, yet even higher toughness. As a result, a titanium core carbon fiber part can take substantial abuse from harsh environments, whereas a carbon fiber part will tend to break easily. The carbon fiber skins on the sandwich panel add the benefit of the low yield properties to the composite. In this case, if the panel is overstressed beyond what a solid titanium part could take without yielding (i.e. beyond the yield stress of a similar component without carbon fiber), the composite will not yield, thus delivering much better elastic properties. For high stress applications a titanium core carbon fiber composite may be the best fit.

Prepreg vs Wet Layup Vacuum Bag

Kumair specializes in manufacturing carbon fiber parts from prepreg. Although wet layup from dry carbon fiber fabric is sometimes necessary, Kumair always tries to utilize prepreg material first, since this typically creates a much higher quality part. Whether woven or uni-directional, prepreg carbon fiber has straighter fibers and lower resin content. This results in a part that is more rigid, stronger, and with minimal voids. Wet layup vacuum bagged parts, such as carbon fiber sheets, tubes, and angles, tend to have much higher resin ratio and void content than equivalent parts made from carbon fiber prepreg. Since the strength and stiffness come from the fibers, minimizing the resin ratio and voids for a given laminate is extremely important, especially for demanding applications. It is not uncommon for a carbon fiber prepreg part to have a bending modulus 30-40% greater than a similar part made through a wet layup vacuum bag process.

Call or email us today to speak with an engineer about our carbon fiber manufacturing capabilities. All composites fabrication work is performed in the United States by US citizens.